Elevate your diamond processing precision with LAZER AIM, the pinnacle of excellence in diamond sawing. Designed to deliver exceptional results, LAZER AIM achieves the perfect balance between quality and quantity in diamond sawing operations. Experience unmatched performance with minimal weight loss, reduced breakage, and a flawlessly smooth cutting surface. Equipped with modern software, LAZER AIM stands as a testament to cutting-edge technology. Its compatibility with MagikCut™ enables intricate pie sawing, while ROBOCUT PRO automates operations for enhanced efficiency. The high-quality laser beam ensures minimal openings during sawing, maximising yield and profitability — making LAZER AIM a game-changer in diamond processing.

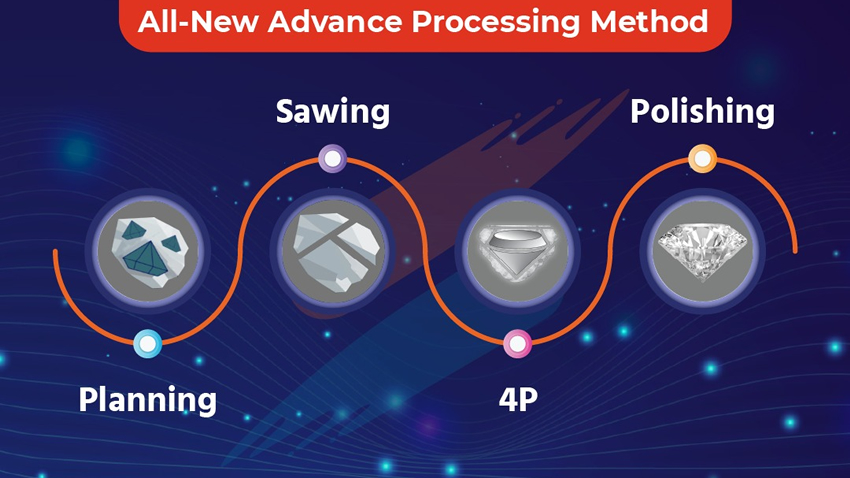

Introducing MagikCut™, a revolutionary advancement in diamond processing technology that eliminates the need for traditional marking. Designed to enhance efficiency and precision, MagikCut™ seamlessly integrates with all STPL diamond sawing machines. This innovative solution not only simplifies the production process but also significantly reduces costs and accelerates output, setting a new standard in the industry. Experience the future of diamond manufacturing with MagikCut™ where accuracy meets speed.

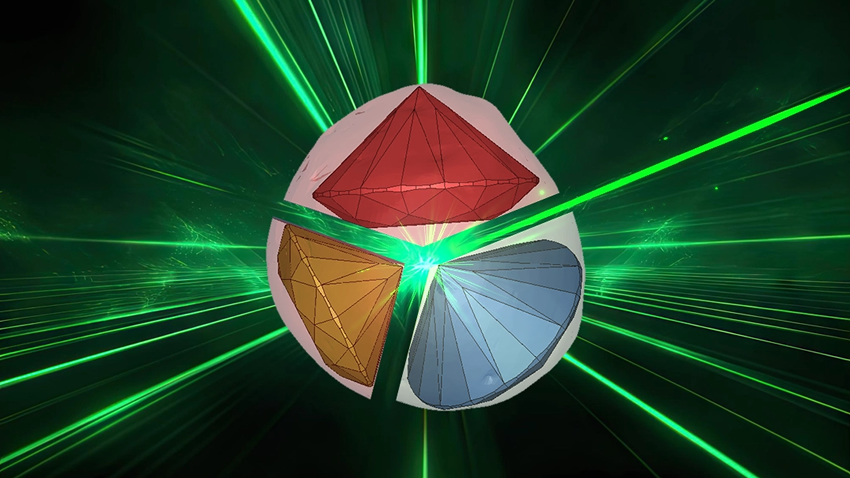

Upgrade your diamond processing speed and quality. Explore our cutting-edge technology, 'FLYING BEAM'™, a revolutionary advance in diamond processing. What distinguishes FLYING BEAM is its innovative approach—unlike traditional methods where the axis moves to process the diamond, FLYING BEAM utilizes a dynamic laser beam that moves, ensuring unparalleled speed and accuracy. Tailored for diamond sawing and shaping, FLYING BEAM produces exceptional results, particularly in the intricate art of fancy diamond shaping. This technology represents the future of diamond processing, showcasing our commitment to innovation and excellence in the industry. Experience the next era of precision with FLYING BEAM™ from STPL.

|

|

High-Precision Sawing

Achieve flawless sawing results with exceptional accuracy. Minimize diamond weight loss and reduce chances of breakage, ensuring every cut enhances the value and brilliance of stones.

Advanced Laser Technology

Choose from three powerful variants — Infrared (IR), Green (GRN), and SPEC TECH. Each designed for unmatched precision, performance, and sawing excellence in every diamond.

Superior Surface Quality

Deliver mirror-smooth sawing surfaces that reduce polishing needs. With reduced surface irregularities, LAZER AIM ensures enhanced clarity, brilliance, and beauty in every processed diamond piece.

Maximum Yield & Profitability

Engineered for efficiency, it minimizes openings during sawing, maximising yield from every stone. Extract superior value, improve profitability, and optimize production across all diamond sizes.

Consistent & Reliable Output

Built for durability and round-the-clock performance, LAZER AIM ensures consistent sawing quality. Reliability and stability empower manufacturers to meet high-volume demands without compromising precision.

Upgrade Flexibility

Future-ready design compatible with multiple add-ons such as Magnus ACE, MagikCut™, and ROBOCUT PRO. This ensures smarter, faster workflows and enhanced automation for diamond processing.