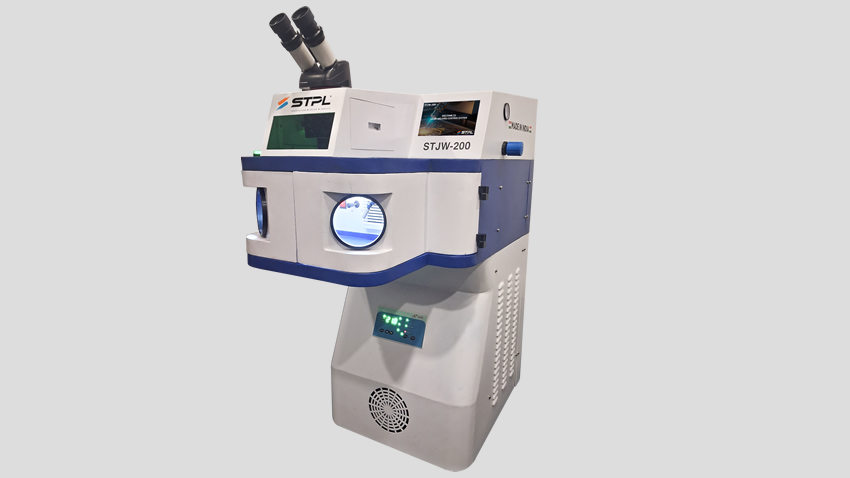

by STPL is a next-generation laser welding machine for jewellery, purpose-built for artisans and manufacturers seeking high precision, durability, and continuous operation. Designed with advanced Nd:YAG laser technology, intuitive controls, and unmatched reliability, it ensures clean, accurate welds on a wide range of precious metals. Whether you're repairing delicate gold chains or assembling high-end custom pieces, delivers consistency with every pulse.

by STPL is a next-generation laser welding machine for jewellery, purpose-built for artisans and manufacturers seeking high precision, durability, and continuous operation. Designed with advanced Nd:YAG laser technology, intuitive controls, and unmatched reliability, it ensures clean, accurate welds on a wide range of precious metals. Whether you're repairing delicate gold chains or assembling high-end custom pieces, delivers consistency with every pulse.

Gold, Silver, and Platinum Jewellery Welding

Jewellery Repairs and Intricate Joining

Stone Setting and Assembly

Custom Jewellery Manufacturing

Pulse Shaping with 16 Custom programs for different metal properties

200W Average & 2.5KW Peak Power for effective joining of various metals

Nd:YAG Flashlamp Laser for stable, high-performance welding

Ergonomically Angled Microscope for strain-free precision work

Built-in Water Chiller for uninterrupted 24/7 operation

7” Touchscreen HMI with Joystick control for intuitive operation

Dual Gas Channels with air-integrated foot pedal and pressure knob (Air/Argon)

Fully Enclosed Welding Chamber to ensure safety and waste containment

High-Tech Flashlamp for Extended Component Life

| Laser Type | Nd:YAG (Flashlamp) |

| Wavelength | 1064 nm |

| Laser Class | Class 4 |

| Max Average Power | 200 W |

| Peak Power | 2.5 kW |

| Pulse Duration | 0.1 – 20 ms |

| Pulse Frequency | 1 – 25 Hz |

| Max Pulse Energy | Up to 50 J |

| Spot Diameter | 0.2 – 3 mm (0.1 mm optional) |

| Cooling System | Water Cooled (Built-in Chiller) |

| Gas Pressure | Up to 5 Bar |

| Control Interface | 7” Color Touchscreen & Joystick |

| Power Supply | 230 VAC, 50 Hz, 3 KW |

| Machine Dimensions | 950 mm x 492 mm x 1260 mm |

| Weight | 150 kg |