In an era where technological advancements are rapidly transforming industries, the diamond processing sector is no exception. Enter MagikCut™, a groundbreaking technology developed by STPL, designed to revolutionize the diamond processing landscape. MagikCut™ is not just a technological upgrade; it is a paradigm shift that promises to enhance efficiency, reduce costs, and increase profitability for diamond processing units worldwide. This innovative solution addresses longstanding challenges in the industry and sets a new standard for diamond processing.

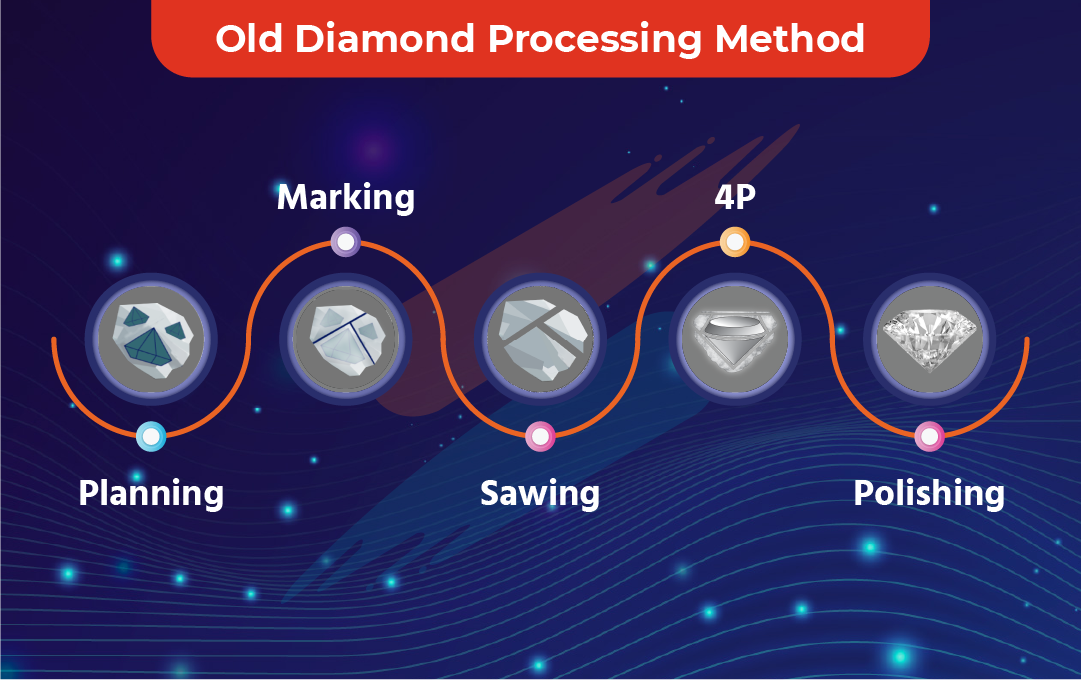

The diamond industry has traditionally relied on a series of meticulous and labour-intensive processes to transform rough diamonds into polished gems. One of the critical steps in this journey is Diamond Marking, a process that ensures precise alignment and accurate cutting. However, marking is time-consuming, requires skilled labour, and adds to the overall cost of production.

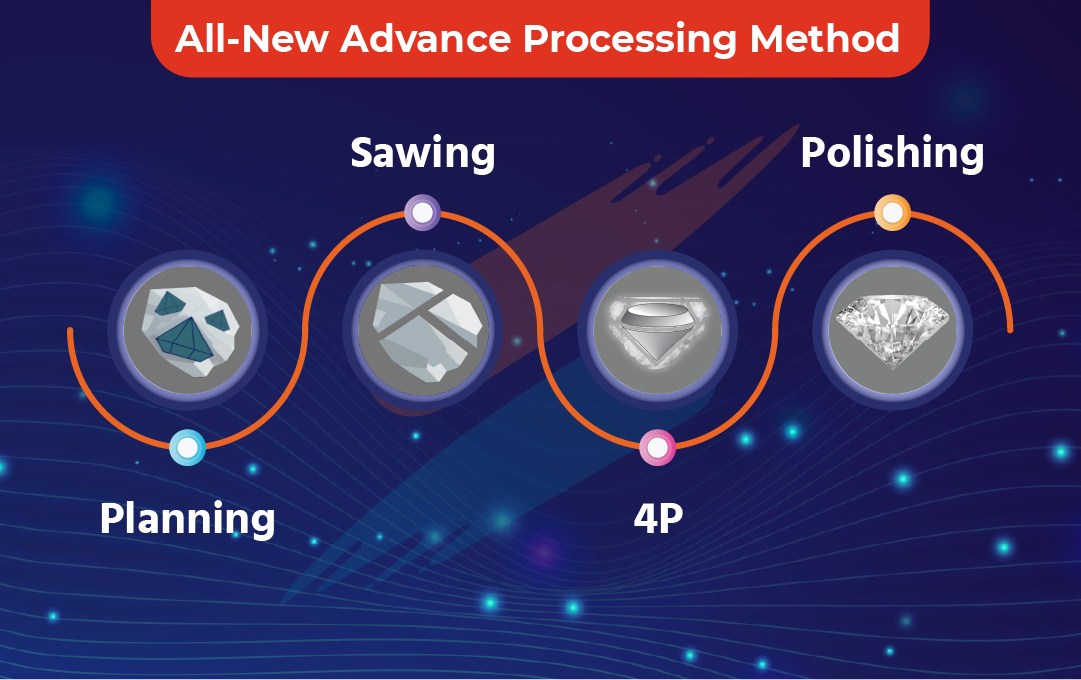

Recognizing the need for a more efficient solution, STPL embarked on a mission to eliminate this cumbersome step. The result is MagikCut™, a technology that removes the need for diamond marking, allowing diamonds to proceed directly from planning to sawing.

MagikCut™ is packed with features that make it a game-changer for the diamond processing industry. Here are some of its most notable attributes

Elimination of Diamond Marking

The primary innovation of MagikCut™ is its ability to bypass the diamond marking process entirely. By doing so, it not only saves time but also reduces the need for skilled labor, cutting down on labor costs.

Enhanced Alignment Precision

Without the need for manual marking, MagikCut™ employs advanced algorithms and automation to ensure precise alignment. This leads to higher accuracy in cutting, minimizing errors and material wastage.

Cost Efficiency

With the elimination of marking and reduced reliance on skilled labor, MagikCut™ significantly lowers the cost of production. This cost efficiency translates into higher profit margins for diamond processing units.

Increased Production Speed

By streamlining the process and removing the bottleneck of marking, MagikCut™ accelerates the overall production timeline. This means that diamond processors can achieve higher output in less time.

Improved Diamond Quality

The advanced technology behind MagikCut™ ensures that the diamonds are cut with utmost precision, resulting in better quality polished diamonds. This improvement in quality can lead to higher market value and customer satisfaction.

Integration with Existing Machinery

MagikCut™ is designed to be compatible with STPL’s existing range of diamond sawing machines. This ease of integration allows diamond processing units to upgrade their technology without significant additional investments.