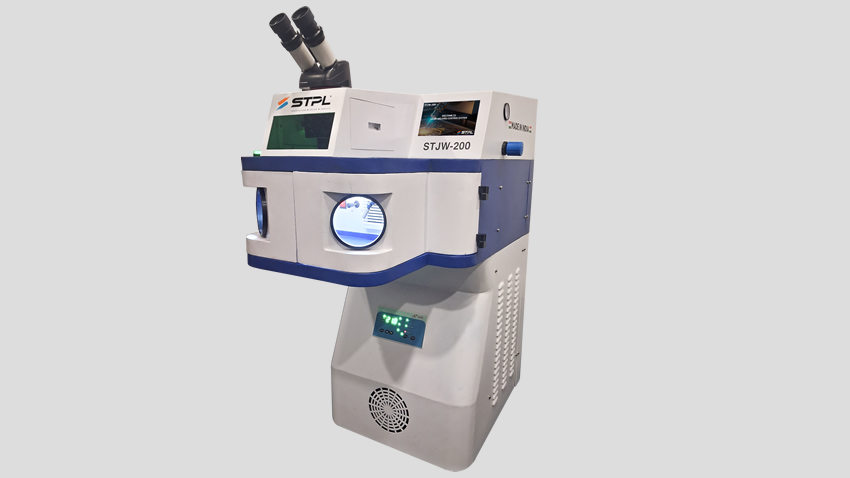

The STJW-200 by STPL is a next-generation jewellery welding machine, purpose-built for artisans and manufacturers seeking high precision, durability, and continuous operation. Designed with advanced Nd:YAG laser technology, intuitive controls, and unmatched reliability, it ensures clean, accurate welds on a wide range of precious metals. Whether you're repairing delicate gold chains or assembling high-end custom pieces, the STJW-200 delivers consistency with every pulse.

Gold, Silver, and Platinum Jewellery Welding

Chain Repairs and Intricate Joining

Stone Setting and Assembly

Custom Jewellery Manufacturing

Nd:YAG Flashlamp Laser for stable, high-performance welding

200W Average & 2.5KW Peak Power for effective joining of various metals

Pulse Shaping with 16 Custom Programs for different metal properties

Ergonomically Angled Microscope for strain-free precision work

Built-in Water Chiller for uninterrupted 24/7 operation

7” Touchscreen HMI with Joystick control for intuitive operation

Dual Gas Channels with air-integrated foot pedal and pressure knob (Air/Argon)

Fully Enclosed Welding Chamber to ensure safety and waste containment

Germany-imported Flashlamp for extended component life