The art and science of diamond processing have undergone a revolutionary transformation over the centuries. From manual planning methods to cutting-edge digital technologies, the diamond industry has evolved tremendously to achieve greater precision and efficiency. Today, as both natural diamonds and synthetic diamonds like.

CVD (Chemical Vapor Deposition) and HPHT (High-Pressure High-Temperature)

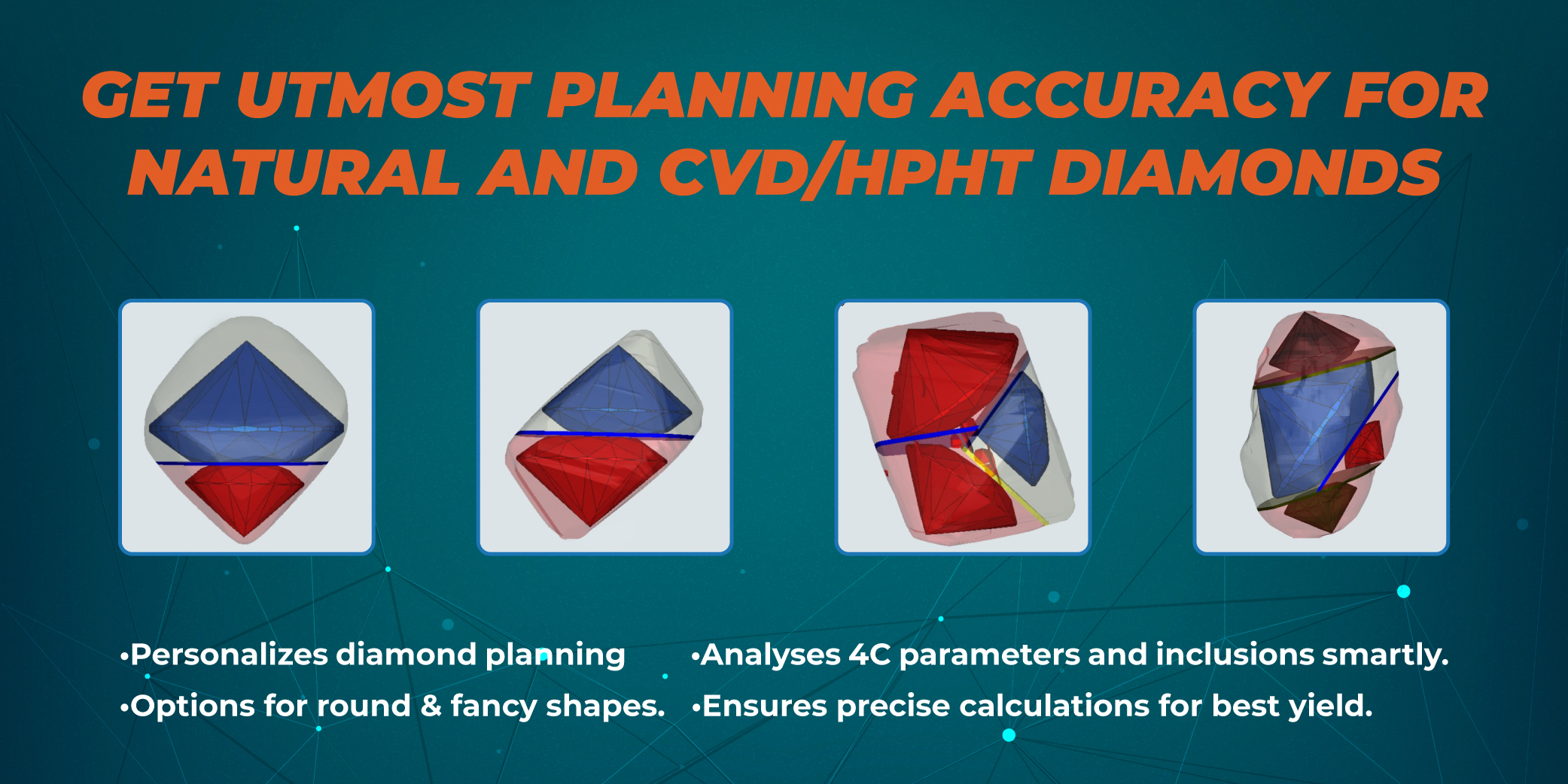

continue to dominate the market, the importance of accurate diamond planning is more critical than ever. This article explores the history, challenges, and modern advancements in diamond planning, focusing on the unique requirements for both natural and synthetic diamonds.

A Brief History of Diamond Planning

Diamond planning, historically, was a manual process relying heavily on the expertise of gem cutters and planners. Artisans would use their keen eye and years of experience to assess the rough diamond and determine the best way to maximize its yield and value. The goal was simple to achieve the perfect balance of weight retention and brilliance.

The introduction of basic machines in the mid-20th century brought a semblance of standardization to the process, but true precision remained elusive. By the 1990s, the diamond industry witnessed a game-changing advancement with the advent of digital diamond planning machines. These machines integrated laser scanning and computerized algorithms, enabling planners to create 3D models of rough diamonds for better analysis and optimized cutting paths.

Today, advanced machines like Magnus Digital Neo and Magnus Digital Lite represent the pinnacle of diamond planning technology, delivering unmatched precision for natural diamonds and synthetic gems like CVD and HPHT.

The Challenge of Planning Natural Diamonds

1. Inclusion Mapping

Natural diamonds are formed under extreme pressure over billions of years. As a result, they often contain inclusions or imperfections. Mapping these inclusions accurately is critical to maximizing the yield while maintaining the stone’s structural integrity and brilliance.

2. Optimizing the 4Cs

Diamond planning for natural stones revolves around optimizing the 4Cs—Cut, Color, Clarity, and Carat weight. A slight miscalculation in planning can drastically affect the final product's value, making accuracy paramount.

3. Retaining Weight vs. Achieving Brilliance

Balancing weight retention with achieving maximum brilliance is a fine art. The planner must decide how to cut the stone to retain the maximum possible weight without compromising its overall appearance and value.

The Rise of CVD and HPHT Diamonds

CVD and HPHT diamonds have gained significant traction as ethical and sustainable alternatives to mined diamonds. However, they come with their own set of planning challenges

1. Structural Variances

Unlike natural diamonds, CVD and HPHT diamonds are created in controlled environments. While they are free of inclusions found in natural diamonds, they may have growth patterns or stress points that require careful mapping during planning.

2. Unique Growth Patterns

CVD diamonds grow layer by layer, which can create irregularities that must be accounted for during the planning stage. Similarly, HPHT diamonds, created under high pressure and temperature, may have unique stress areas that need to be avoided during cutting.

3. Demand for Custom Shapes

With synthetic diamonds, there’s a growing demand for customized shapes and designs. Advanced planning machines must cater to these unique requirements while ensuring high yield and consistent quality.

Modern Diamond Planning Technology

Machines like Magnus Digital Neo and Magnus Digital Lite from STPL have set new benchmarks in diamond planning accuracy. Let’s delve into the technological advancements that have made modern diamond planning machines indispensable.

1. Advanced Scanning and Mapping

Equipped with superior laser scanning technology, modern planning machines can create detailed 3D models of rough diamonds. These models capture even the smallest inclusions, grooves, and irregularities, ensuring a precise cutting path that minimizes wastage.

2. Smart Planning Algorithms

Today’s machines use advanced algorithms to analyse the 4Cs and generate multiple planning options, such as Plan by Value, Plan by Weight, Twin Planning, and Best Saw Plan. These features allow operators to make informed decisions for achieving optimal results.

3. In-House Software for Security and Efficiency

Unlike unauthorized and non-licensed planners, machines like Magnus Digital Lite come with proprietary, in-house-developed software. This ensures high security, seamless operation, and consistent results.

4. Multi-Range Digital Lens

Planning machines now feature adjustable lenses that accommodate diamonds of various sizes without requiring manual adjustments. This capability enhances versatility and productivity.

Why Accuracy Matters in Diamond Planning

1. Maximizing Yield

Accurate planning ensures that the maximum possible carat weight is retained from the rough diamond, directly impacting profitability.

2. Reducing Wastage

Precision planning minimizes material loss during the cutting process, an essential factor for both natural and synthetic diamonds.

3. Ensuring Consistency

With advanced planning machines, manufacturers can achieve consistent quality across all diamonds, meeting stringent market standards.

4. Catering to Market Trends

The growing demand for custom shapes and fancy cuts requires machines that can plan intricate designs with accuracy and speed.

The Future of Diamond Planning

As the diamond industry continues to evolve, the need for accurate and efficient planning solutions will only grow. Advanced machines like Magnus Digital Neo and Magnus Digital Lite are poised to lead the way, offering unparalleled precision and versatility.

Whether you’re processing natural diamonds or exploring the potential of CVD and HPHT diamonds, investing in cutting-edge planning technology is the key to staying competitive in today’s dynamic market.

Diamond planning has come a long way from its manual roots to today’s high-tech solutions. For both natural and synthetic diamonds, accuracy in planning is the cornerstone of profitability, quality, and customer satisfaction. STPL’s Magnus Digital Neo and Magnus Digital Lite stand at the forefront of this revolution, combining speed, precision, and security to redefine what’s possible in diamond processing.